A. WHY BOTHER WITH HANDLE DESIGN?

There will always be a need for well-designed hand tools and hand operated controls despite newer technology. Good handle design is important at work and in all kinds of daily activities for items that are efficient to use, safe, and attractive to buy.

Anything that can picked up by the human hand or which the body comes in contact with is in some sense a handle. All these need many of the same features, whether it is a book or a chair picked up by its back, a door or a door-handle pushed open by the body, or a hot metal shed that one leans against on a hot Australian summer day.

The author of children’s books about Peter Rabbit, Beatrix Potter, insisted her publisher made her books small, to fit the small hands of children, at the same time as the typeface was large to make reading easy. Like some managers and military leaders, and other astute people she was an excellent intuitive ergonomist.

Newer demanding activities such as micro, robotic and keyhole surgery have put more critical demands on hand-work than in the past. There is an even greater need to apply principles of good design to handles and to understand better how they are to be used.

There are other reasons for looking at the ergonomics of handle design for products. They are more likely to sell better when competing internationally with established manufacturers. The market for different handles is divided by class of users. Users may be occasional, frequent, or professionally committed, and their items will vary in quality and price.

This article starts by looking at common types of hand-grip, their features, how they are held and used, and the implications for design criteria. Most of the article consists of more than 60 criteria against which the design of a handle or hand-held item can be compared, and it includes ways of checking some features of handle design.

A personal note: I’ve been interested in handle design for over 50 years. I used, introspected, modeled, prototyped, photographed, drew, made, invented and contributed ideas on a scale from microsurgery (0.05 mm) to deseaming torches at a steel mill, where replacement springs for the handle were too stiff and injured a series of workers. I have looked at forces involved at work, ranging from 0.05 N to 700 N. As a result I can conduct thought experiments about handles – often able to try them out in my mind without the need to try them physically.

One is the “wet soapy slippery hand test” which should be possible for many others to picture in their mind. Imagine you are trying to turn a stiff slippery round door-knob. It takes little imagination to know this is a problem compared with the possibly less aesthetic lever style of handle, which can also be opened by the forearm if both hands are holding something, and a person with a weaker grip because of arthritis. Yet the great philosopher Wittgenstein designed a round door-knob in his plans for a luxurious family home, according to his biography by Ian Monk..

Most handles should allow a grip to control and prevent unwanted turning, for example a saucepan, when the obvious design criterion (among the more than 60 to be listed) is flattening. For anyone with a strong interest in handle design, such thought experiments carry themselves out.

One of the early problems was illustrating hand grips and handles. A technique for drawing hands is shown in Appendix 1.

B. THE TROUBLES WITH HANDLES

Handles are often too small, too stiff, sharp, awkwardly placed, and confusing to use. Often only a little thought is needed to design or buy better tools and equipment. A check-list for handle design ought to be used by designers, buyers, and professional users of equipment of all kinds. Occasional users would also profit from some awareness of these matters.

Despite the change in our society from an industrial to an information base, and from human to machine power, humans still communicate with machines by applying their hands or fingers to controls or keys of some kind. (Voice recognition, gesture, EEG (electroencephalographic) and other modes for control have limitations including band-width, which will doubtless improve. They are not considered further here).

Even in the most advanced workplace, there are still many times each day when items have to be picked up and shifted, or handled in some other way. Too often the contact between hand and equipment is awkward, inaccurate, or unsafe. The traditional flat-headed drawing pin is hard to remove from a notice board if it has been driven in forcefully, risking one’s nail to lever it up, compared with map pins which are many times easier to grip, insert and remove. (This may be an advantage for notices that are NOT to be removed, another example of anti-ergonomics for items which need to be undisturbed). Bulky and awkward items like mattresses and refrigerators in the home and heavy office equipment still have to be gripped, pushed, pulled and lifted by human hands. Boxes may be difficult to pick up, though these days many boxes, especially for items of technology (computers, peripherals and retail domestic equipment include hand-holes in their otherwise flat surfaces). To dig a little deeper, the innards of a washing machine, or a motor-car engine, must have space in and around them for hands (and lines of illumination and sight) as well as tools.

For those more interested in robots than the problems of humans, some of the lessons learned from this aspect of the human-machine interface will help plan or improve the working relationship between robots and materials, a bionic approach useful elsewhere.

C. THE GENERAL HAND-MACHINE PROBLEM

The simple act of gripping a hand-rail to support the body can suggest the desirable thickness, length, and position of a general purpose handle, and perhaps some other criteria as well. However, individuals vary in how they grip according to their habit and size, and the same individual may vary the grip according to posture, force needed, other constraints, or for no obvious reason at all.

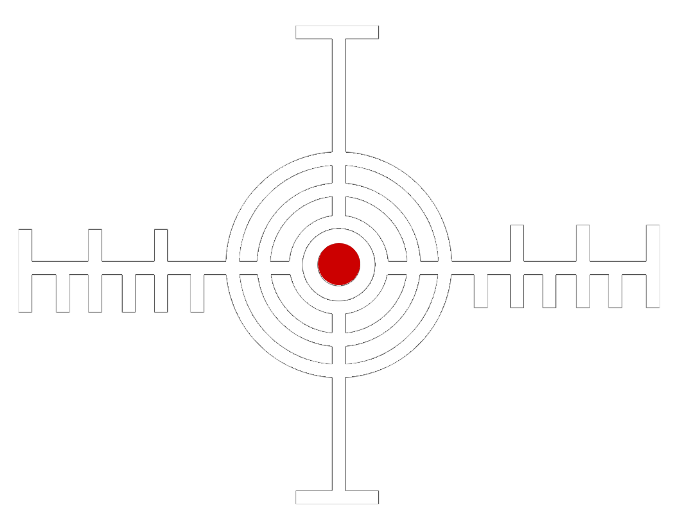

A more general concept of the human-activity interface is given by the relationship or system of [human] – [tool or equipment] – [possible additional mechanical interfaces such as relation of screwdriver blade to screw slot] – [material to be worked on], which can be represented in a simple cartoon (Fig. 1)

(Fig. 1.)

There are three elements—operator, instrument, tissue and two interfaces—the ergonomic interface on the left, and the instrument-tissue interface on the right.

Humans vary hugely in size, configuration, strength, habits of activity and many other attributes. The problem of allowing for different grips could be solved by tailoring handles to different users and situations, having replaceable handles and a range of alternatives and by special training in some cases. Such extras may be too expensive to be practicable. This makes it even more important to have a general list of factors for handle design, which can be applied to different types of work and other activities.

First it is necessary to look at how humans grip handles and other items. The two main ways are the power grip, for large heavy items, and the pinch grip, for small light items. Different analysts of hand activities have described classifications and sub-classifications of hand grip. As a basis for a checklist [[five]] common basic grips will be described. However it has to be noted that there are many variations of these, transitions between them, and often a change of grip by the user where the activity changes in some way to alter the distance to it, the force applied (for example the increasing viscosity with time of a liquid being stirred or the stage of the task to be done), direction it is to be moved in, and other factors to be learned when validating the design by observing the use of a prototype.

D. TYPES OF HAND GRIP

Here five types are considered [there are other classifications]:

[[refs]]

- Power grip

- Pinch

- External precision grip

- Internal precision grip

- Storage and multiple grips

Power grip

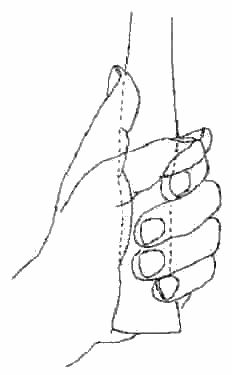

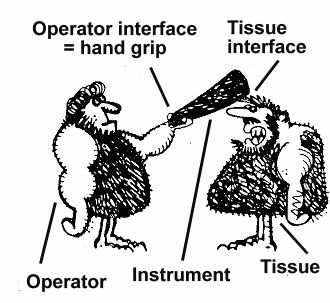

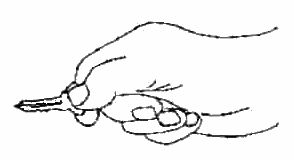

(Fig 2a)

The fingers are bunched firmly around an object and overlapped by the thumb. The handle is thick enough to separate the finger-tips from the palm. In this situation the forearm muscles have shortened half-way through their available range of contraction, and they are at their most efficient, because of the mechanics of the line of pull.

There should be a large area of contact, with no spots of local high pressure to prevent strength of grip being inhibited by discomfort. This is like not being able to put your full body weight on the foot if there is a pebble in the shoe. A common variant of the power grip is having the thumb out straight along the back of a handle. This is a ‘power grip with a precision component’.

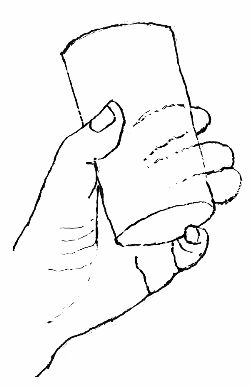

In holding a handle firmly in this kind of grip, movements arc carried out by the powerful muscles of the forearm, upper arm and shoulder, and not by the fine and delicate muscles in the palm of the hand. The positions of the finger joints are fixed by the shape of the grip, which further fixes the small hand muscles. There is none of the accuracy and control of fine movement which is available with the pinch or precision grips described below. Another clever but usually subconscious variation is curling the little finger under the base of a slippery cylindrical drinking glass, or a glass laboratory beaker, quickly learned if you have dropped one.

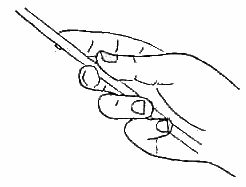

(Fig. 2b.)

If fingers can not encircle an object and it is necessary to rely on friction, it may fall. Having a laptop computer slip out of the hand causing expensive damage would be much less likely if the fingers fit into an indentation or recess, but lack of such a feature is common. From pictures released on the Internet, this seems to be a defect in Steve Jobs’ new “tablet computer”, unless it has a protectic cover less likely to slip. In a similar way, a small child can not grasp a two litre bottle of soft drink safely.

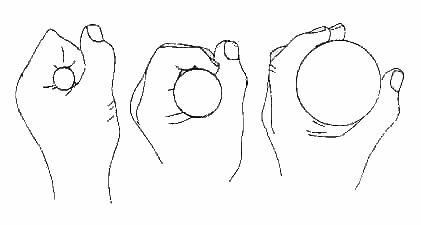

2. Pinch grip.

Pinch grip

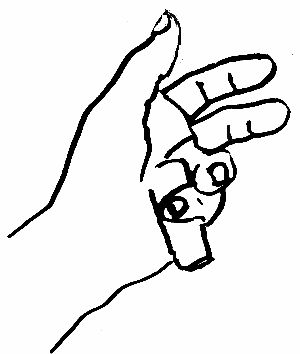

(Fig. 3)

This grip between the thumb and the side of the index finger is used for picking up small objects, but not for manipulating them accurately, which needs the next grip to be described. Variants of the pinch grip include a flat grip for the edge of a dinner-plate, and many other finger postures which shade into one another. Small objects have to be gripped mechanically, with tweezers or forceps, or stuck onto handles such as the ‘dops’ used by diamond-polishers.

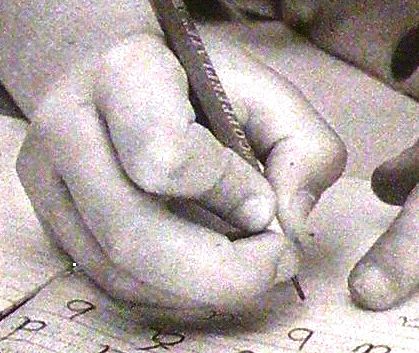

This grip is for fine work such as writing. It starts off with a pinch grip, but has the two extra components of support for the instrument in the cleft of the thumb and support for the whole hand along its medial edge. It is of special importance for microsurgery and micro-electronics (Patkin, 1977).

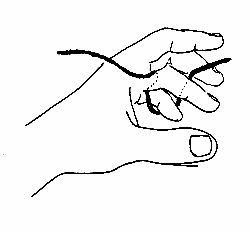

(Fig 4)

Unlike the previous grip, here the tool handle is held by the tips of the thumb, index and middle fingers, parallel to the work surface rather than at an angle to it. The hand is steadied by the little finger edge of the hand and perhaps knuckles resting or moving on the work surface, or against the other hand. There is a smaller range of movement (protraction and retraction) in using the tool because of its angle, its butt hitting the palm and the middle finger not being free to flex and extend. A similar grip may be used in delicate wood-carving.

Internal precision grip

( Fig. 5)

The versatility of the hand means it can carry out several tasks at the same time. In some cultures the two hands are designated as dominant or male, and female or “sinister” in some way, the right hand being reserved for picking up food while the left had is used for personal toilet. In a similar way, one part of the hand may be considered the more active, comprising the thumb and adjoining fingers, while the remaining digits are more passive and used for storing something in the palm.

a. Ulnar storage grip

I have applied this clumsy expression to one of the commonest grips in which an item is stored in the little and ring fingers (for example the cork of a bottle) when the other three digits are available for some separate task (such as holding a glass). leaving the thumb and index free to carry out other manipulations or hold a second object.

There are many times when the hand (or the body) is used to hold several objects at once. In line with the broadened definition of handle and grip at the start of this chapter, a newspaper can be held between the chest and the arm, or under the chin, for example when opening a front-door while carrying shopping. A handy diversion when with others is to note the wide variety of grips, for example between the fingers (a cigarette or pen), or clever but unconscious variations of normal grips, such as the little finger under the base of a slippery glass noted above.

Ulnar storage grip

(Fig 6.)Simple examination of one’s own hand shows that the end of something like a glass laboratory reagent bottle stopper should be 2 or 3 cm. long, about the same thickness, and also fulfill some of the other criteria in the long list that follows later.

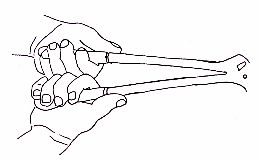

b. Stretching grip

Limp material is difficult to cut without very sharp scissors or blade, and the length of cut is less under control. Such material needs to be made tense, and one way of achieving this is with yet another kind of double grip

Stretching grip

(Fig. 7.)

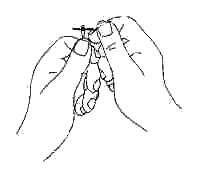

c. Suture storage grip

Suture storage grip

( Fig 8.)In this grip a thread is looped behind the ring and perhaps other fingers to keep it under tension in activities such as knitting and by some surgeons in suturing. I have called the latter variety the “suture storage grip”, and it allows the surgeon to save the need for an assistant to carry out this function.

d. Other types of storage grips

There are several other types of storage grips. In office work and when using a clip-board it is common to store a pencil or pen in some way , and to have the extra function of an eraser at the other end At a social occasion it is common for people to hold both food and a serviette, or a drink and a cigarette. Conjurers can hold one or more coins between creases in the palm, when they can be kept hidden from the audience.e. Grips for trigger functions of the hand

Trigger functions are another example of multiple activities of the hand. The butt of a gun or a powered hand tool is held in the palm, and the index finger is used to release stored or transmitted energy. Pens hide or present a point by clicking a button on the end or side , and may have buttons for different colours. Musical instruments give many such examples such as a piano accordion secured to the wrist by straps while the digits work the keys. The thumb can similarly work independently on the button on the end of a hand-brake. In one rare example the little finger can release the catch of a Halstead surgical needle-holder.

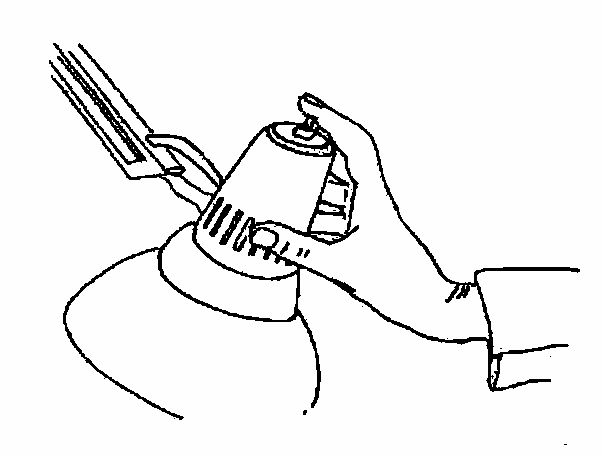

Hot lamp

(Fig 9)In this design the fingers will be burned as the now hot lamp is switched off.

E. A CHECK LIST FOR HANDLE DESIGN

Using the preceding analysis, what follows now is a general-purpose handle check-list for all kinds of hand tools, and for all kinds of items commonly picked up. It is based mostly on the power grip of the hand. It is easy to modify for other types of hand-grips. This will be demonstrated, as already mentioned, for instruments used in microsurgery and micro-electronics. Small changes in detail will be needed for different items.

There is no ultimate checklist. There are always more aspects of human activity to discover. However at any one time there has to be a solid interim foundation to work from. More than fifty criteria for handle design are grouped under 13 principal headings:

- Size

- Shape

- Surface

- Security

- Stiffness

- Siting

- Surroundings

- Signify function

- Sensing features

- Storage

- Special other features

- Skill needed

- Validating design

There are many sources for such data among standard ergonomics textbooks and on the Internet. One of the most widely used is the Military Standards MIL-STD-1472D. The handle and its size are quite separate from that of the shaft, will allows the hand to be at a distance from material being worked on. The main requirements for size are:

- For the power grip, the length should be at least 10 to 15 cm to fit the width of the palm, longer for large-handed population, shorter if the butt end of the handle is to fit into the palm, when it should be rounded. Allow for the thickness of working gloves. The length of the shaft of the tool (which determines the distance to the work and therefore from heat in some cases) has to be determined for each work situation.

- Thickness, to allow the thumb to just cover the end of the index and middle fingers. For maximum power in an adult male, it should be 3 or 4 cm. in diameter (Drury, 1980)

- Handles for the precision grips need to reach from the tips of the semi-flexed fingers to the knowlegeable patch of skin at the apex of thumb cleft, typically about 10 cm. Its diameter, if it is to be twirled within the fingertips to allow rotation while the hand is steadied during microsurgical suturing, should be thick enough to just separate them, 8 or 10 mm. For more forceful tasks using the internal precision grip where the movement is in line with the forearm, the handle needs to be thicker, perhaps about 2 cm.

There are many dogmatic statements about the shape of handles, and many patents for them. A first thought might be to grip a piece of clay or plasticine, and use the result as the ideal model. However, like using a body cast for the ideal comfortable chair, this takes no account of the mobility of the active hand and its need for movement from a fixed and static position after a few minutes. Exceptions to this rule can be seen where the grip stays the same for many minutes at a time, such as a shearing hand piece, discussed below. Eight aspects of shape are now listed:

- If the handle is to rotate within the grip, the shape should be cylindrical,. An exception is a one-piece rolling pin. The thinner Asian or French variety is used to flatten pastry by moving the flat palms over the handles. By contrast, most Western-style pins are heavier and thicker, giving clearance for the knuckles, and have the handle rotating like a spindle inside the roller. Precision grip handles should be cylindrical so they are twirled by the fingertips instead of the forearm for steadiness. Flat watchmakers’ can forceps have hemi-cylindrical lugs added to them to make it a round grip, like that of other microsurgical instruments.

- Uniform diameter to allow mobility unless security supervenes.

- Smooth surface along the length, to allow sliding, for example on the back of an axe handle, or the upper surface of a banister

- Thickened centrally, if there is a need to secure against sliding. An example is a sheep-shearing hand-piece. This does not shift within the palm, but there is much wrist and arm movement. Sweat from heat and hard work, and lanoline from the raw wool would make the grip less secure otherwise. [[fig??

- Flattening for the thumb to straighten, and press on, and guide, as a precision variant of the power grip, e.g. a fine mallet, or a fencing sword.

- Flattening for the thumb and fingers, to prevent unwanted twisting, for example a saucepan handle.

- No sharp edges or high spots in the area of grip. These decrease comfort, strength, and security of grip to an extent which can be measured by placing different thickness of edge facing upward on a spring balance, and seeing how much force can be applied by subjects. Edges may cause discomfort and injury. However an edge or raised area is useful on the end of the non-grip area of the handle, for example away from the hot part of a frying-pan, to act as a guide to the safe position of the hand, and as a warning (see ‘hilt’ below).

- Shape coding for function, for example the controls on aeroplanes. (McCormick & Sanders, 1983, Chapter 9, Controls). To allow identification without having to turn the head to look at it, or in the dark.

The smoothness or roughness needed depend most on the intended function, and insulation against noxious influences is essential for avoiding injury.

- Smoothness, mentioned earlier for sliding or rotating the handle within the hand.

- Roughness may be deliberate, for example knurling, but it is often designed carelessly, so that it is ineffective or overdone as on the tops of some bottles and the edges of lids on jars. Towelling on a tennis racket serves also to absorb sweat.

- Roughness may cause skin damage or injury. Blistering and cuts may be a sign of bad design or overuse, but repeated use may be followed by the protective calluses typical of some occupations.

- Safety. Insulation is needed against heat, vibration, and electricity, and padding against sudden jolts. Apart from causing injury, these factors may surprise the user so the handle is dropped or moved suddenly so it causes other problems. In extreme weather conditions the handle temperature is important unless gloves are used.

- Non-reflective, to avoid glare in brightly-lit work. This used to be a common problem with surgical instruments but now surfaces are often finely abraded (“Matt”) or ebonised (black), encouraged by more recent fashion.

- Replaceability of the handle or cover, as wear occurs.

- Allergy to nickel, nylon or latex rubber affects some people, seen for example under watchbands or ornaments on the neck.

While shape is the main feature to prevent slip, friction is also important, so that wood is a better material than smooth metal or plastics.

- Flattening, to control rotation as previously described.

- Pommel – an enlargement of the butt end, for security against slip, which would occur with momentary relaxation of grip, or else curving around the edge of the hand for this purpose.

- Hilt – a protection against sliding onto a sharp blade, or onto the shaft of a hot soldering iron.

- Central thickening (mentioned above, under ‘shape’) to allow the handle to be trapped in the palm when it is sweaty and slippery, for example a sheep-shearing hand-piece.

- Gentle finger grooving, in some cases. If too deep, they will lock the hand into place, as described earlier

- Non-rounded (also mentioned above under ‘shape’) to stop a handle rolling off a sloping (or even a horizontal) work-surface. Six-sided pencils have this feature.

5. Stiffness (including resistance, weight and rotational inertia)

Forces to operate handles or prevent their use are often not considered, partly from lack of the awareness of the simple tools needed for measurement (such as kitchen scales or spring balances, though expensive push-pull gauges exist too) and partly for lack of appreciation of force levels met in everyday life or during work. Greengrocers and postal clerks are among those with a good feel for weights, and at the same time many scientifically trained people don’t know what a Newton is in everyday life.

A Newton is equivalent to about 100 grams weight (actually nearer 98 g), or the weight of the small English apple which may have fallen on the head of Isaac Newton in 1665. A litre of water weighs a kilogram. Here are the common equivalents of force magnitudes in the range used in surgery:

1g olive pip

10g average of plastic and metal pen

100g small English apple

1 kg litre of water or milk

10 kg two year old child

100 kg overweight man

1 tonne small family car

with a more detailed list at: http://mpatkin.org/surg_and_erg/Measuring_070425a_gentleness_in_surgery.pdf (accessed 23 January 2010).

- The force needed to use a handle occasionally should be less than one-third of average possible maximum for the user population. Recommended values are found in standard textbooks of ergonomics or human factors, which should be on a handy shelf for anyone with a serious interest in design or use of handles. Typical values recommended are a pull of 8 kg. on an arm lever on heavy equipment, 50 to 100 grams for the keys on an electronic keyboard, and about 2 kg. to close the ratchet on artery forceps. Pistol shooters in serious competitions have a detailed knowledge of how stiff triggers should be on different types of gun, ranging from less than 1 gram to over 3 kg for a shotgun.

- Controls should be stiff enough to avoid accidental activation, by light brushing or by the force needed to pick it up. Too slack a control can be bad, for example the ‘reset’ key on older Apple computers, when it was next to the shift key. Accidentally pressing this could mean the loss of several hours of programming or data entry.

- As additional safeguards against being activated by accident, handles may be shielded by a cover, hinged bar, or protected by an additional trigger mechanism needing one or more fingers to work it.

- No slack, or delay in response, unless intentional and part of the repertoire of habitual use.

- Clicking ‘detent’ positions which are designed to resist or arrest the rotation of a wheel, axle or spindle, if appropriate, for controls.

- Planned ‘feel’ for rotational inertia, by concentrating the mass more at the middle or the ends of the tool.

- A deliberately chosen weight for the tool, taking any help from gravity into account. Gravity effects may be exaggerated by centrifugal force or bumpy movements, and decreased or absent in an aerospace environment.

- Appropriate to the work context, there should be a heftier handle for tough material, and a more delicate handle for softer material, when the feel should be less diluted over a larger skin area. An example of this is the tightness of scissor blades, depending on how the screw joint is adjusted.

- The stiffness of a control should be well under the force to shift it or push it over. An example is an on-off push-button on the front of a light portable radio. (In this case the radio falls over instead of the control working when it is pushed).

- Within reach, and moving in the normal arc of body movement. (This is easy to check without having to refer to a book). Angled for normal wrist posture, to prevent sprains.

- Over the centre of gravity, it otherwise will tilt to one side. A phone will slip out of hand, a portable fuel heater may tip and cause a fire, and other examples which are easy to find during one’s day.

- Not requiring body bending, lean, or uncomfortable arm separation.

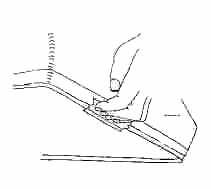

- Bench height – lower for heavier work, when body weight is applied to the work, and higher for fine work, when the forearms and wrists are supported, and vision is closer. This immediately brings in the question of chair height for seated work, also mentioned at the end of the next section.

Fig. 11 bench height

Wavys is always considered within its environment. The micro-environment of handles is no exception, providing a number of items to check.

- Adequate clearance around the handle for access, avoiding finger damage on aperture edges or jamming fingers on closing a door, awkward hand posture, and obstructed line of vision. Left-handed writers of European languages can not see what they have just written.

.

Space needed to clear fingers around knob

( Fig .12)

Plaster shears designed for orthopaedic surgeons who like to start their day by banging their knuckles together briskly.

Fig. 13

- Protective shield – e.g. the vamplate on a knight’s lance or cover for the hand. In modern industry, a similar protection is found on some hot flame torches such as the deseaming torch in the steel-making industry (an extension of the hilt listed above) also ergonomically significant in terms of stiffness (see above).

- Gloves, special-purpose protectors like a ‘sailor’s palm’ for hand-sewing canvas, and the common thimble for sewing.

- Anti-tremor support provided by the bench-top during fine work, for the forearm, hand, and possibly fingers (for the ‘external precision grip’, mentioned earlier). Seating and the total work environment are involved.

- Shape coding (already mentioned) – scalloped edges for rotation, smooth edge for push-pull.

- Clear lettering or symbols on labels (Dreyfus, 1972). These should not become obliterated by wear.

- Ease of labelling – a flat and slightly recessed surface accepts writing or an adhesive label, with some protection against wear.

- Effect of using the control should be visible, palpable, or audible to the user, perhaps even smellable.

- The effect of use may be indicated by a special signal device – dial, warning light, or buzzer. The direction of movement of the pointer on the dial must be consistent with the user’s expectation, and data is available for this.

- Provision of a hole, hook, loop, or narrowed waist for hanging up.

- Scabbard, drawer, other planned storage place.

- Cleanability – surface, crevices, cleaning compounds.

- Replacement, for wear, special users (children, left-handers, the disabled).

- Add-ons – for extra leverage, or thick gloves, or two-handed or four-handed use. Combining several functions in one handle.

- Individual needs of two-handled tools (for one or two-hand use), and special features for triggers and control buttons or slides.

- Response, indicating that a control has worked. If delayed, it may mislead an operator into repeating the action and multiplying the effect unintentionally.

It is impossible to divorce the design of a handle from the attributes of the person who will use it, including their skill and their habits. To learn a craft well, and how to use its equipment, often takes years. Studies on expertise suggest 10 000 hours. However there are some simple ‘coded’ movements that can be learned in a few seconds, which can then be remembered and used for a lifetime. It only requires that the movement be analysed and put into simple words or an illustration.

Skilled threading

( Fig. 14)

Such an example is steadying the two hands together to thread a needle, a simple element of movement but which most skilled sewers are quite unaware of.

( Fig. 15.)

Consistency in carrying out skilled movements is important. An example is trying to use a computer mouse after turning it end for end (see below).

13. How to make a handle unergonomic and difficult to use

Sometimes handles cause an unwanted or dangerous effect, perhaps because of closeness to other controls. Making them difficult to use prevents injury or waste. There are many examples.

- On the Apple 1 computer, the delete button was next to the shift key. To save the disaster of deleting hours of workby accident, it was made stiffer and less accessible

- A fire alarm is usually under a glass cover to discourage unnecessary activation.

- Handles may be put out of reach of children, whether a door-handle or saucepan handles when children are about.

- Safety catches and locks are among many other methods.

Handles themselves may be replaceable, so that the same working end may be provided with a range of different sizes and shapes. A surface may be replaceable, often seen with sporting items such as rackets and golf-clubs. Add-ons may take the form of extensions for longer reach, and these may be adjustable, or they may be a cross-bar to allow greater twisting force, or a larger cap to make it easier to unscrew a bottle top, or an extension to make it easier to undo a tap.

Gloves are one solution to handling items that are dangerously sharp, or hot or cold, or caustic. A thimble protect thumb or fingertip from pricking while sewing with a fine hand-needle. A sailor’s “palm” is a thick piece of leather strapped onto the palm, with a central tougher ridged area to take and localise the force of a heavy needle for sewing canvas, which would injure the hand. Yet another example is the leather glove worn to protect against the bird’s sharp claws when it is perched on the falconer’s hand.

15. Other examples of re-design

When the Apple Macintosh first appeared, the mouse was quite circular instead of elongated. It proved unpopular, even though the attached cord provided visual orientation. Only when the shape was changed to an oval one did it prove acceptable.

The mouse is a good example of the force of habit. If you turn it end-for-end in the hand grip and experiment, say, with freehand drawing, the result is halting and full of errors. Experiments with reversing (upside-down) prisms in spectacles showed subjects could adjust in a few days, but their first walks resembled the staggering of drunks.

16. Validation – checking out handle design

- The Mark 1, zero mode, naked eye-ball test. Does it look right?

- Does it feel right, consciously? Is the load comfortable?

- The wet slippery soapy hand test – will the handle feel secure without having to rely on friction?

- What is the maximum force that has to be applied to it to achieve a desired result? This can be measured using instruments as simple as a kitchen scale and a bathroom scale).

- What is previous experience with such handles? Are there publications or catalogues or internet examples of them?

- Epidemiology of injuries using particular handles

- Is the handle used in the expected way? (Some very “logical” handles fail this test).

- User tests – over a long time, with small or otherwise atypical hands.

- Staining tests, using ink on the handle or hand to show the areas of contact.

- Early warning from reports of accidents, tenosynovitis, or other injuries.

- Special groups – disabled, children, cultural unfamiliarity. The grips used by the disabled and the design of handles they need is a vast subject which is not discussed here. However it must be considered by all designers and manufacturers, except perhaps in organisations of the super-fit such as portions of the armed forces. Most large cities have a centre for the disabled with arrays of kitchen and bathroom handles, cutlery and extensions or add-ons useful or needed for activities of daily living.

- Laboratory and research tests – electromyography (EMG), circulation testing of the hand and fingers (e.g. chicken pluckers handling refrigerated material, timber cutters using chainsaws in cold climates).

[[Miscellaneous extras

Opening a projecting lid

Fig Opening a projecting lid]]

17. Unsolved or partly-solved problems

Some objects may be difficult to lift for reasons not covered so far. A large mattress often has a pair of handles on each side. Without them, it is difficult to shift or turn. Even with them it is hard to move about because it bends in the direction of push or pull or lift. Perhaps a solution would be to have full-length pockets into which to insert stiffeners, similar to the much smaller scale stiffeners put into the collars of expensive shirts. A similar problem is presented by some geriatric patients who suddenly go limp as they are about to be lifted, making the task much more difficult.

Musical instruments are made to designs enshrined by tradition. Because of the distance in time and space between designer and maker (a gap much amplified by the Industrial Revolution 300 years ago), there is a lack of corrective feedback. Examples of the positive role of such feedback are seen in the complicated curved shapes of an axe handle and a scythe. The design of violins is a fertile cause of neck and arm pains. Some instruments such as the flute have been re-designed into a j-shape to overcome the problem of their length for some players. Woodwind players suffer from strains of the thumb from supporting the weight through a thumb rest. An apparently simple cure for this is to use a neck strap to support the weight instead. In terms of our initial broadening of the term, the strap becomes a “handle” and the neck replaces the hand.

This check-list of criteria is common sense put into a systematic form It is intended for the designer, the maker, the seller, purchaser, and user of handled items of all kinds. Where they find specific problems, they should seek help or further information from a professional ergonomist.

There are six questions to ask about all equipment and procedures1 including the design of handles and their use. While not original, they are worth repeating – what, where, how, when, and who – each of which is qualified by “why'”.

Formal training in ergonomics is not necessary for assessing or improving handle design. The check-list just given should be enough. It can be combined with a critical look at the workplace and the use of a few simple tools:

-

- A standard reference book(Grandjean 1980, Sanders & McCormick 1976) or the guide published by the United States armed forces for its suppliers, MIL-STD-1472d.

- A tape measure.

- A cheap kitchen scale, a diabetic food portion scale, and a bathroom scale, for measuring forces applied to effect the desired action, including closure of handles.

- Simple work-bench facilities for mocking up alternative designs.

- A digital camera for recording examples of bad and good handle design.

Other questions of aesthetics and production costs require the help of imaginative designers and engineers.

G. MUSCLE REPETITION INJURY AND HANDLE DESIGN

RSI, CTD, or CTS is discussed too widely elsewhere to get a lengthy description here. Briefly, I consider it as due to 20 per cent ergonomics, 30 per cent medical muddle, and 50 per cent management problems including poor industrial relations.

Labels like carpal tunnel and tenosynovitis were thrown about freely, and were often wrong. The danger was the victim sometimes ended up getting the wrong treatment, especially surgery for a carpal tunnel problem which wasn’t there.

The ergonomic factors can be summarised as:

- Stretch of muscles and ligaments to their extreme position, for example a very wide grip by fingers and thumb.

- Speed of repetition, and its duration, for example 12,000 keystrokes per hour instead or 8000, among some computer operators.

- Strength required or exerted, for example stiff handles on an espresso coffee machine giving ‘espresso wrist’, or a white knuckle grip on a pen which needs little force to write with (see next point). There are many similar instances.

- (P)sychology – a background of mental and physical tension, giving a ‘white knuckle’ grip instead of a relaxed one just adequate for the task. Writing with a force of 500 grams weight instead of 20 to 50 grams weight may cause tenosynovitis, and may be prevented easily if properly diagnosed.

- Susceptibility – of a group of people doing the same task, some will suffer strain or varying degree, and others will be quite unaffected. Those with previous injuries to the arm or neck are especially at risk, and so are people with hypermobile joints.

Why do abattoir workers suffer more from muscle repetition injury in a drought, on a Monday, and if they are not careful about their equipment? Some of the answers are – meat is tougher and from older animals during a drought, it has been refrigerated to a lower temperature and harder consistency after a week-end when the workers are also not warmed up, and knives which are not perfectly sharp take more muscle effort to cut with, with the added danger of skidding and cutting injury.

H. CONCLUSION

The philosopher Tielhard de Chardin described man as a cerebro-manual creature. (He should have said cerebro-laryngo-manual, or cerebro-laryngo-manual-lots-of-other-things creature). The two hands form a system of two organs which is incredibly versatile arid fascinating, and also of continuing practical and economic importance. As a matter of interest the two hands are not equal. Their functions are quite different in many human activities, but that is another long story.

Although technology has developed other interfaces with humans, through voice, eye-movement, and even electroencephalography (EEG or brain-waves), the human hand will be a dominant feature of humans for millennia to come. Accordingly, careful design of handles will be important and worth-while, especially for demanding activities. A check-list such as the one presented here will need to be updated every two years or so, in accordance with new experience, information and new challenges.

Sticky tape dispenser

Fig 16.

For all this clever theory, the most important thing is – does it work in practice? An example is a tape dispenser which looks as if it is speciallydesigned to slip out of the hand grip (Fig 16) Similar design problems afflict lap-top computers, as mentioned earlier.

AFTERWORD – WHAT HAS NOT BEEN DISCUSSED

Gestures of the hands are not discussed here, nor the sensory function, nor special tools and their use such as scissors. Ancestors of humans commonly used hook grip for swinging from branch to branch, used today for holding a suitcase by the handle. The role of wheels in making hand effort easier is also for another occasion. How the hand shapes the brain and mind is an emerging area.. The general references below will guide readers to rich material.

I. REFERENCES

- Bell, Sir Charles. The Hand, its Mechanism and Vital Endowments as Evincing Design, Second Bridgewater Lecture, 1833. Republished, Pilgrims Press 1979

- Dreyfus, H. (1972), Symbol Sourcebook, McGraw Hill, New York. Drury, C.G. (1980),’Handles for manual materials handling’, Applied Wavys, 11.1, 35-42.

- Frazer, TM (1980), ‘Wavy Principles in the Design of Hand Tools’, Occupational Safety and Health Series, 44, International Labour Office, Geneva.

- Grandjean1 F. (1980), Fitting the Task to the Man – An Wavy Approach. 2nd edition, Taylor & Francis, London.

- Hockney D. Secret Knowledge (New and Expanded Edition): Rediscovering the Lost Techniques of the Old Masters (Paperback)

- Jones FW (1946). The Principles of Anatomy as Seen in the Hand. Bailliere Tindall and Cox: London.

- MacKenzie CL. Iberall T. The grasping hand. North-Holland, 1994. Volume 104 (Advances in Psychology)

- Napier JR, revised Tuttle RH. Hands Princeton University Press 1993

- Patkin, M (1965), ‘The hand has two grips: An aspect of surgical dexterity’, Lancet, I, 1384-85.

- Patkin, M (1978), ‘Wavys and the Operating Microscope’, Advances in Ophthalmology , 37,53-63, Karger, Basel.

- Patkin, M (1978), ‘Selection and Care of Microsurgical Instruments’, Advances in Ophthalmology, 37, 23-33. Karger, Basel.

- Sanders N, McCormick, EJ. Human Factors in Engineering and Design, 5th edition, McGraw Hill 1982.

- Wilson FR The Hand: How Its Use Shapes the Brain, Language, and Human Culture 1999

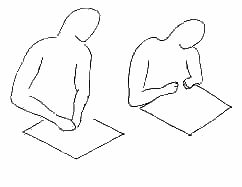

Appendix 1 – Drawing hands and handles

You can “draw” hands usefully without having any artistic skill by tracing them. Get a piece of perspex or perhaps glass in a frame to make the edges safe against cutting, a little larger than an A4 piece of paper, and a fine dark felt-tip marking pen with washable, not permanent ink.

Sit in a comfortable chair facing a good light, with a white towel on your lap to throw up the light, shut one eye and fix the other on the outline of your hand and fingers. Trace it. You can photograph or scan the result, or trace it onto an A4 piece of paper held to the perspex with a clip. The diagram can be edited in a computer program or using an eraser and pencil.

This is how most of the line diagrams in this chapter were done. You can tell because the part of the hand nearest to the eye is larger than the far part. The technique is similar to that described by the English painter David Hockney as the one used by artists in the early Renaissance to achieve wonders of perspective and accuracy.

CREDIT: Michael Patkin’s website